Glassfiber Reinforced Epoxy (GRE) Pipe Systems

You Should Know

In supporting the successful deliveries of marine scrubbers installations on vessels (to comply with IMO’s 1st Jan 0.5% SOx cap), BOS has transformed to become the material stockist of GRE (Glass Reinforced Epoxy) pipes, which are essential for SOX (Sulphur Oxide) scrubbers and BWMS (Ballast Water Management System) installations for vessel retrofitting projects. BOS also specializes in turn key solutions in GRE pipes supplies, pre-fabrications, engineering designs, installations and commissioning.

- Green specifications- 25% of the weight of traditional mild steel pipes, immune to corrosion

- Reduction in weight of vessels equates to reduced fuel consumption

- Free from maintenance and replacement requirements

Manufacturing

to your needs.

Save

more.

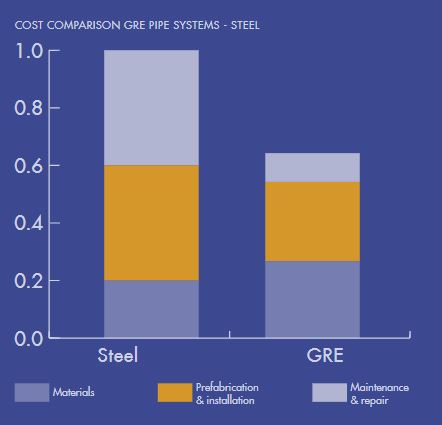

GRE cost comparison to steel

Naval Marine Applications

Rigorously and successfully tested for use onboard naval vessels, both Wavistrong & Fibermar are suited to many applications onboard both future and current generations of warships and submarines in service throughout the world.

Tangible benefits to both the naval shipyard and the Navy; Fibermar & Wavistrong are typically 60% lighter than CiNiFe, are highly resistant to erosion & bio-fouling, have a service life in excess of 25 years, are more cost effective to procure than CuNiFe, require no maintenance and installation cost and time are also dramatically reduced.

Prefabrication

By spooling the pipes and fittings, installation time onboard can be significantly reduced with the bonus that installation costs are also reduced. Typically 70% of the spools for a job are prefabricated in controlled conditions either in FPI facilities, in shipyards or at the workshops of our preferred contractors.

Spools will be tested before leaving our workshops to ensure the quality of our product. Additionally, prefabrication reduces the number of bonded joints, and hence reducing the use of chemicals onboard.